You have no items in your shopping cart.

0item(s)

You have no items in your shopping cart.

With Hawk Performance Talon brake rotor and pad kits you are one click away from a performance brake upgrade. Manufactured to work seamlessly together, the Hawk Talon kits include your choice of Hawk brake pad compound coupled with a pair of their high quality Talon rotors. Order a kit for the front and the rear.

The Hawk HPS compound, in most cases, will provide increased brake torque and operating temperature when compared to OEM pads. There will also be a decrease in brake dust. With an upper end operating temperature of 800-900 Deg F, the HPS compound can withstand light track use as long as you are aware of the signs of over-heating and allow proper cool off time when the pads approach their upper temperature. The Hawk HPS compound is not a race compound and it can not withstand prolonged race sessions at high temperatures. Concerning brake dust, the HPS will be cleaner than your OEM Pads, but create more dust than the Hawk Ceramic compound. The performance improvement over Hawk Ceramic comes at the cost of increased dust production.

Hawk Talon Drilled & Slotted rotors are a quality high carbon rotor that will last and perform well on street applications. The slotted only version will hold up to moderate track use, but expect to see higher rates of wear when used with aggressive track pads.

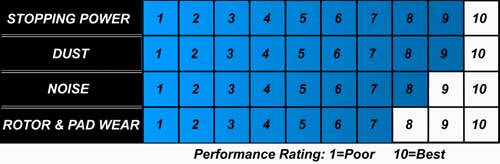

Hawk HPS (High Performance Street) brake pads are world renowned for increasing stopping power on your street driven vehicle. Increasing the performance of your vehicles braking system is easy when you choose Hawk Performance's HPS braking compound. This unique Ferro-Carbon formula was developed for street performance using the safety and quality of Aerospace and Motorsports severe-duty friction technology. The High Performance Street compound offers a higher coefficient of friction over stock brake pads and can provide you 20-40% more stopping power and higher resistance to brake fade than most standard replacement pads. Less fade means you'll have a highly durable brake pad with less brake dust

Decades of experience, continuous research and development, and dedication to bringing the highest quality premium friction products have led to Hawk Talon Rotors. Leveraging the high quality performance of Hawk Performance's unique and proprietary DTC curved slot design, they are built to OE specifications, weights, and production processes, and are engineered to fit a vehicle's current braking system without modification.

Hawk's Talon Slotted Disc Brake Rotors are precision engineered, machined, finished, and weather-fortified in North America to ensure durability and enable to pass the ISO-9227 salt-spray test for long-lasting good looks even on notorious salted roads. For improved brake pad "bite", the racing style hook-slots from Hawk's renowned DTC racing rotors have been integrated into these new performance street brake rotors using precision CNC machining.

Sold and priced in pairs, an ideal choice for high performance driving, towing and even track days. Hawk Talon Truck Brake Rotors - Ideal rotor upgrade for towing or high performance driving. Made in North America by Hawk for select vehicles, check your application.

Hawk Rotors are Engineered, machined, finished, and coated in ISO certified facilities in North America Hawk TALON ROTORS® produced from Grade 3000 Cast Iron-black coated Validated and verified brake rotor design and performance characteristics through extensive brake dynamometer testing Proven cross-drilled designs to optimize thermal efficiency, heat dissipation, strength, and improve wet braking Hawk Talon brake rotors are balanced and incorporate precision milled slots to reduce harmonic resonance issues Exclusive and proven Hawk DTC Slotted design is CNC integrated into heavy duty slotted-rotor only applications Black Magni brake rotor coating barrier applied that maintains superior corrosion resistance and ensures quick and easy bed-in that resists galling and is Salt-spray tested per ISO-9227, exceeding the 240 hours requirement.

WARNING

WARNINGThis product can expose you to Silica, crystalline (airborne particles of respirable size), which is known to the State of California to cause cancer. For more information go to www.P65Warnings.ca.gov

Carlisle Brake & Friction (CBF) warrants Hawk Performance branded products to be free of defects from workmanship and materials. This warranty does not apply to normal wear or damage caused by negligence, lack of maintenance, accident, abnormal operations, or improper installation or service. CBF does not make any other warranty claims, either expressed or implied, including the implied warranties of merchantability or fitness for a particular purpose. In no event will CBF/Hawk Performance be liable for incidental or consequential damages of any kind, whether such damages are claimed on account of breach of warranty, breach of contract, negligence, or strict product liability. This includes without limitation, damage to property, or other economic losses that may be incurred. Any, and all, warranty claims must be processed through CBF. All valid warranty claims will be replaced and/or reimbursed with Hawk Performance® branded products of equal or greater value.

* Disclaimer to “Limited Life-Time Warranty”: Motorsports brake pads and rotors are developed for high performance events. Racing is a dangerous sport. Hawk Performance racing brake pads and rotors are sold without warranty expressed or implied. No warranty or representation is made as to this product’s ability to protect the user from injury or death. The user assumes that risk.